&w=3840&q=75)

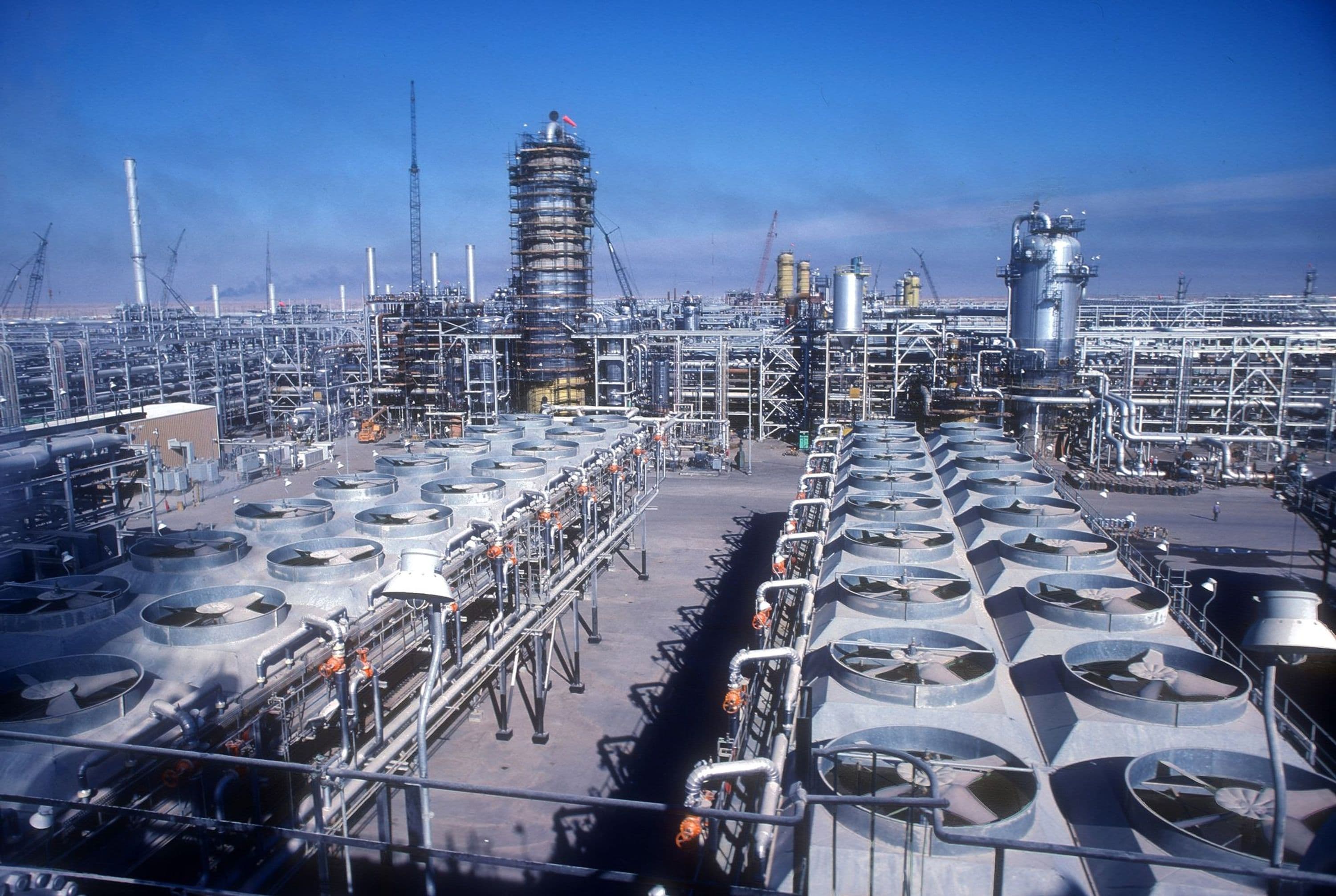

Saudi Aramco Gas Program - EPC

Client: Saudi Aramco

Location: Eastern Province, Saudi Arabia

Business Segment: Energy Solutions

Industries: FuelsEnergy Transition

Executive Summary

ARAMCO, at the request of the Kingdom of Saudi Arabia in 1975, needed to construct the largest gas gathering and processing system undertaken at that time in the hydrocarbon industry, including the design and construction of the world's largest offshore liquefied petroleum gas (LPG) loading terminal.

Fluor's relationship with ARAMCO spans 70 years and includes many of Saudi Arabia's major gas processing and pipeline facilities, starting with the construction of a major facility expansion for ARAMCO in 1948, Fluor's first project in the Middle East.

Client's Challenge

In the 1970s Saudi Arabia's oil reserves far exceeded those of any other nation. In order to make the crude suitable for pipeline transmission, storage, and export, approximately 500 cubic feet of natural gas had to be separated from every barrel of oil.

In 1975, the Kingdom of Saudi Arabia requested that ARAMCO construct and operate the largest gas gathering and processing system ever undertaken at the time in the hydrocarbon industry. The gas-gathering program would comprise facilities throughout Saudi Arabia at locations that include Shedgum, Uthmaniyah, Ju'aymah, Berri, Jubail and Yanbu. The terminal at Ju'aymah was to be the world's largest offshore LPG loading terminal at the time.

The system was designed to process more than three billion standard cubic feet per day (scfd) of sour gas feed. The total daily production capacity of the new system was two billion cubic feet of sweet dry gas, 375 million cubic feet of ethane, 300,000 barrels per day of export liquid products and 3,700 tons of sulfur.

In May 1980, the first ocean-going tanker took on product at the newly completed Ju'aymah fractionation center and LPG terminal, a portion of what many called the world's largest gas conservation project.

Fluor's Solution

Fluor's role in the expansive Gas Program for ARAMCO included engineering, procurement support, construction management and major construction activities for a substantial portion of the program's activities.

The engineering scope of the ARAMCO Gas Program involved more people in more offices than any other project in Fluor's history. Between 1975 and 1982 more than 18 million work hours were required to accomplish our engineering scope of work. Our offices in Houston, Texas; London and Manchester, UK; Haarlem, Netherlands; and Dusseldorf, Germany contributed engineers to this massive undertaking.

The Project Directorate was located at the Fluor Arabia Limited office in Dhahran.

Each Fluor office had specific responsibilities. The Houston office managed work in Europe and the United States and was also responsible for engineering on the Shedgum and Uthmaniyah Gas Plants and the modification of 25 Gas Oil Separation Plants (GOSPs) at Shedgum and Uthmaniyah. Our offshore group engineered more than 500 miles of gas gathering pipelines to bring the associated gas from the GOSPs to the gas plants. The UK office engineered the Berri gas plant modifications, and the office in the Netherlands engineered fractionation centers at Ju'aymah and Yanbu.

The construction portion of the project consumed over 125 million work hours.

Conclusion

Fluor was instrumental in the startup of ARAMCO's massive gas processing and production program. Our engineering workforce peaked at 3,000 employees working on eight task forces in five offices. We also managed 7,000 construction workers.

Operational start-up on some segments of the program was achieved three months early in the spring of 1980 with other facilities phased in over the next two years.

This program was one of the major milestones in Fluor's more than 70-year relationship with ARAMCO.

&w=3840&q=75)

Project Gallery

&w=3840&q=75)